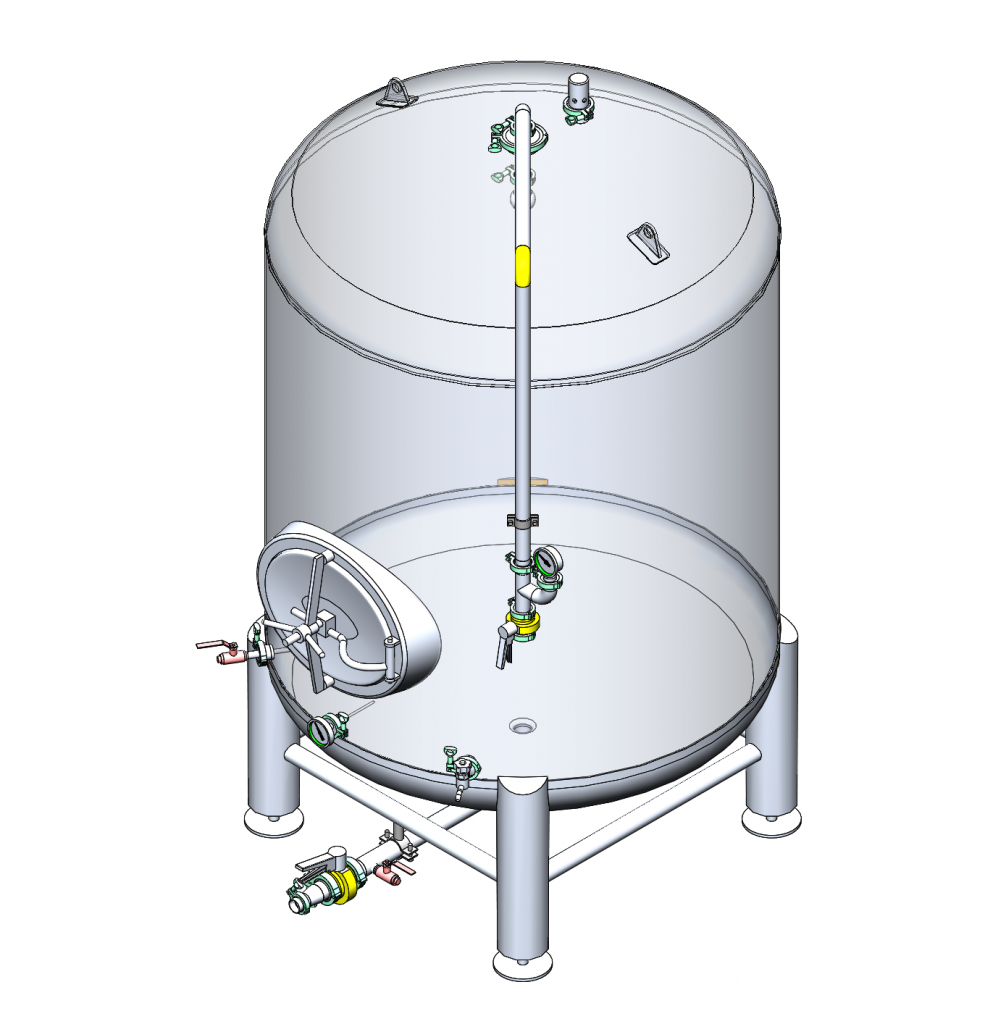

SKE SERVING TANK

SKE serving tanks / systems are made with high quality stainless steel and manufactured by our specialist team of engineers and fabricators depend on different industry & working conditions.

Serving Tank

A.Cold room-Brite beer tank(non-insulated, vertical or horizontal, cooled with air)

A very large number of breweries and pubs, now have their own cold rooms for storing beer, using serving tanks instead of kegs. Simple and cheap non-insulated tanks, cooled by cold air. The traditional way of cooling in a lager cellar. The advantage is low cost and saving place.

B.Brewery warehouse or Pubs normal room-Jacketed Serving Tanks

Jacketed tanks are double walled, having a cooling coil between shells, which holds cold glycol, to chill the beer on demand. The cooling is turned on and off automatically by a solenoid connected to a control panel.These tanks are in a normal room and all tanks are controlled individually. So, they can be set at different temperatures. Advantages of Jacketed Serving Tanksare individual

C.Bag-in-tank for Pubs

The primary application of the Bag-In-Tank system is for the storage, transport and distribution of beer. This might be transport from the brewery to the bottling plant, or even directly to the bar or pub, where beer can be drawn directly from the tank.

Bag-in-tank with a plastic bag intended to storage of finalized beer or cider and for dispensing of carbonated beverages directly from tanks into glasses in pubs and restaurants

The tanks are equipped with a special plastic bags for safety storage of beverage. It allows the pressurizing of tank by non-filtered air without a contamination of beverage by air. Beverage is separated from air with the plastic bag. It allows the pressurising of the tank by non-cleared compressed air without a contamination of beverage by air, because the beverage is isolated from air by the plastic bag inside the tank. We produce the serving tanks as non-insulated (cooled by air) or insulated (cooled by cold water).

Main advantages of this kind of the bag-in-tank :

1), Beverage can be pushed from the tanks using only pressurized air without any filtration

2), Saving costs for inert gases like carbondioxide, nitrogen, biogon etc.

3), The tanks need not be chemicaly cleaned and sanitized after each use. Only drinking water and hose is enough to clean of the tanks one time per month

4), Easy and quick exchange of the plastic bag before a new filling of the tank

5), Beer or other beverages served directly from tanks into glasses taste more freshly and have better sensoric characteristics than drinks served from stainless steel kegs, petainers or bottles

D.BEER DELIVERY AND EVENT BEER TANKS

SKE Beer Systems has considerable experience with events equipment, such as a stand-alone event beer tank. The beer tanks are insulated and have a cooling system and air compressor. Connect the tap, plug in and dispense the beer. Plug-and-play! This set-up saves a lot of time and money compared with beer kegs. The event tanks of SKE are fully stand alone operating units. Because they are fitted with a cooler and compressor, the event tanks are able to be used at any location as long as power is supplied. This allows the user to have a constant flow of cold and perfectly fresh draft beer throughout the event.

Here are the benefits:

1), No need to change kegs (time is money)

2), No pre-chilling or cooling of kegs

3), No pumping loss

4), Space-saving (1x 1,000 litre beer tank = 20 kegs x 50 litres or 50 kegs x 20 litres; lower logistics and operational costs).