Stainless Steel Fermentation Tanks Indoor or Outdoor

To ensure optimum quality, brewers recommend thoroughly sanitizing the yeast brink and parts between every batch. Usually, depending on the volume of yeast, it is advisable to run off the first few gallons of yeast slurry that first flocculated to the bottom. This yeast is the least vital and would not be ideal for re-pitching. The number of generations that may be re-pitched is dependent on the strain, but over reusing may result in mutations that may eventually change the desired fermentation characteristics of the yeast strain.

- Capacity from 1hl to 300hl (Larger ones will be done on site)

- Food grade SS 304 construction

- Top dished head with pressure vacuum relief valve

- Tank Top Device-Optional

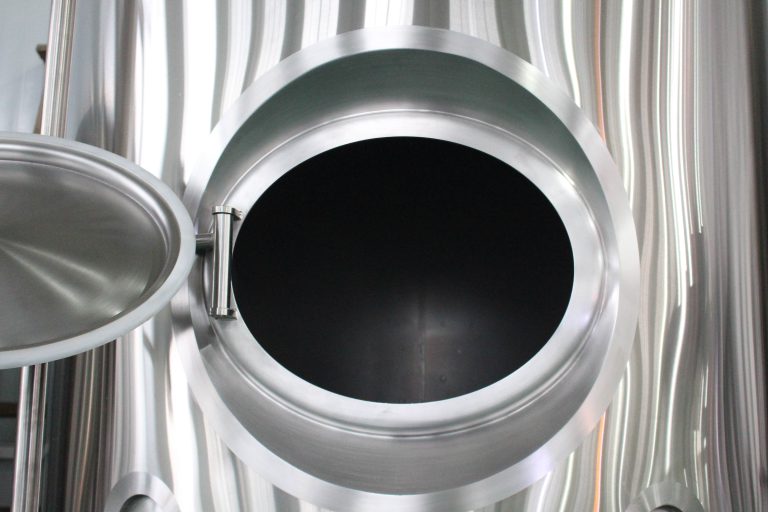

- Top manway or side manhole

- Dry Hopping port (In pressure dry hopping device optional)

- Sanitary CIP rotary spray ball

- 3” PU foam insulated

- Cooling dimple jacket on cylinder and cone bottom

- Side CIP arm assembly with bung valve and pressure gauge

- Sanitary grade thermowell in the side

- Sanitary grade sample valve

- Sanitary grade racking arm in the cone

- 60 degrees cone bottom design

- Bottom discharge

- Four legs adjustable feet, optional for anti-seismic

- Internal shell: 2B, Ra≤0.6 External Shell #4 polished

- Available pressure certificates of PED for 2014/68/EU, AS1210 etc