Introduction

In the brewing industry, maintaining cleanliness and hygiene is essential to ensure the quality and taste of your beer. One of the most critical pieces of equipment in this process is the best keg washer. A high-quality keg washer ensures that your kegs are properly sanitized, free of contaminants, and ready for the next batch. Without proper cleaning, residual yeast, bacteria, and leftover beer can cause contamination, leading to spoilage and inconsistent flavors. Investing in a reliable keg washer can improve efficiency, reduce labor costs, and enhance the overall brewing process. Whether you run a small craft brewery or a large-scale operation, having the best keg washer is a necessity for maintaining high-quality production standards.

The Importance of a High-Quality Keg Washer

A poorly cleaned keg can lead to contamination, spoilage, and off-flavors in your beer. This can result in dissatisfied customers and potential losses. A reliable keg washer eliminates these risks by thoroughly cleaning and sanitizing each keg before reuse. Ensuring proper keg sanitation is not just a quality control measure—it is a fundamental requirement for breweries aiming for consistent flavor and customer satisfaction. Investing in the best keg washer means that every batch of beer is stored in a clean, bacteria-free environment, ultimately preserving its freshness and intended taste.

Benefits of Using the Best Keg Washer

- Enhanced Hygiene: Removes residue, bacteria, and yeast buildup effectively, ensuring a contaminant-free storage environment. Proper sanitation reduces the chances of unwanted flavors developing in your beer.

- Efficiency Boost: Speeds up the cleaning process, allowing for higher keg turnover and reducing downtime between batches. More efficient operations lead to higher production output without compromising quality.

- Labor Cost Reduction: Automates cleaning, reducing the need for manual labor and allowing your workforce to focus on other critical brewing tasks. By reducing reliance on manual scrubbing, breweries can increase productivity and lower operating expenses.

- Improved Beer Quality: Eliminates cross-contamination and preserves the intended flavor profile of your beer. A poorly sanitized keg can introduce foreign bacteria and compromise even the most carefully crafted brews.

- Longer Keg Lifespan: Proper maintenance prevents damage and extends the usability of kegs. Regular cleaning with the right keg washer helps maintain keg integrity, reducing the frequency of replacements and saving costs over time.

Key Features to Look for in the Best Keg Washer

When selecting a best keg washer, there are several key features to consider. These features determine the efficiency, reliability, and effectiveness of the cleaning system. A well-designed keg washer should not only clean efficiently but also minimize water and chemical waste while ensuring a thorough sanitization process.

Cleaning Cycle Efficiency

Look for a keg washer that provides quick yet thorough cleaning cycles. Efficient cycles mean faster keg turnaround and increased production capacity. A slow cleaning cycle can create bottlenecks in production, while an overly fast cycle may not provide sufficient cleaning. The best keg washers balance speed with effectiveness, ensuring kegs are properly sanitized without unnecessary delays.

Automated vs. Manual Operation

Automated keg washers reduce the need for manual intervention, saving time and labor costs. However, some smaller breweries may opt for semi-automatic or manual systems due to budget constraints. While manual keg washers are more affordable, they require additional labor and effort. Automated systems, though more expensive, can clean multiple kegs with minimal supervision, allowing brewery staff to focus on more important tasks.

Number of Kegs Processed Per Cycle

Consider whether the keg washer can clean multiple kegs at once or if it is designed for single-keg operation. Large breweries may require multi-keg capacity for increased efficiency. If your brewery produces high volumes of beer, a multi-keg washer will help streamline operations and prevent backlogs in the cleaning process.

Water and Chemical Usage

The best keg washer should optimize water and chemical usage to minimize waste while ensuring proper sanitation. Look for systems with efficient recirculation and filtration features. Water and cleaning solutions can be costly, so a washer with resource-efficient mechanisms will save money while being environmentally friendly.

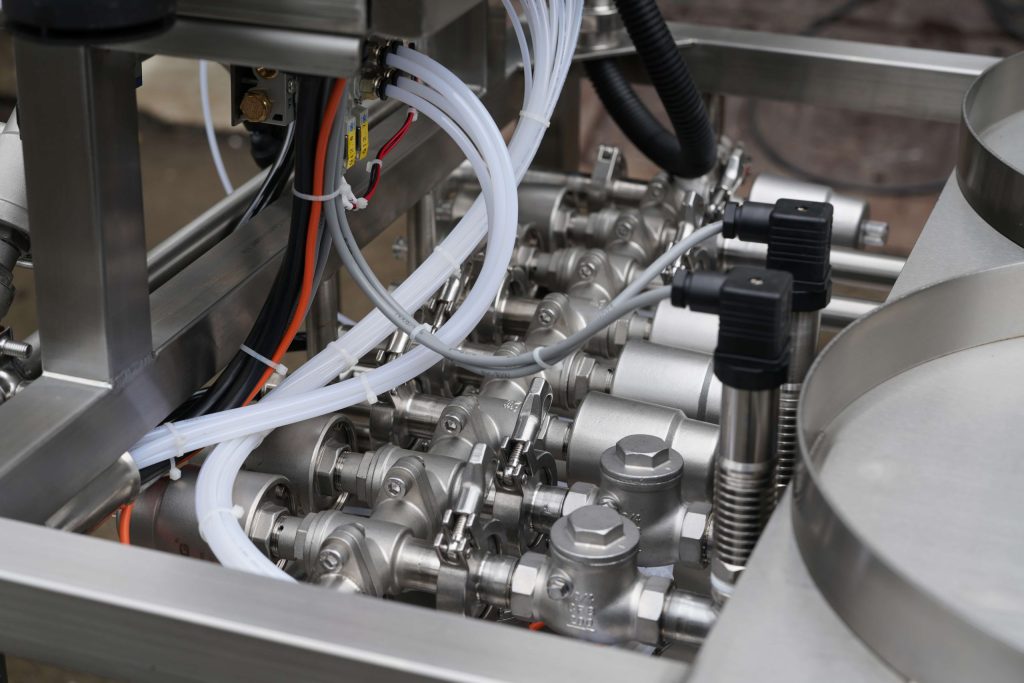

Compact and Durable Design

Space is often a concern in breweries, so choosing a compact yet durable keg washer is important. Stainless steel construction ensures longevity and resistance to corrosion. A well-built keg washer withstands frequent use and harsh cleaning chemicals, making it a long-term investment for your brewery.

How the Best Keg Washer Improves Brewery Efficiency

Investing in a best keg washer significantly improves operational efficiency in several ways. A high-performance keg washer not only saves time but also enhances overall brewery hygiene, leading to better product consistency. Breweries that optimize their cleaning process can increase production capacity without compromising beer quality.

- Faster keg turnaround: Allows breweries to reuse kegs more quickly, ensuring continuous production and reducing downtime between batches. This is particularly important for high-demand breweries with tight schedules.

- Consistent cleaning performance: Ensures every keg meets sanitation standards, preventing cross-contamination and spoilage. Standardized cleaning means no keg is left improperly sanitized, reducing the risk of customer complaints.

- Lower operating costs: Reduces labor and cleaning material expenses, making the brewing process more cost-effective in the long run. The initial investment in a high-quality keg washer pays off through reduced maintenance and cleaning supply costs.

Table: Comparing Different Keg Washer Features

| Feature | Manual Keg Washer | Semi-Automatic Keg Washer | Fully Automatic Keg Washer |

|---|---|---|---|

| Cleaning Speed | Slow | Moderate | Fast |

| Labor Requirement | High | Medium | Low |

| Water & Chemical Efficiency | Low | Moderate | High |

| Initial Cost | Low | Medium | High |

| Suitability for Large Breweries | No | Limited | Yes |

Common Mistakes to Avoid When Using a Keg Washer

Even with the best keg washer, improper usage can lead to ineffective cleaning. Many breweries fail to maximize their keg washers due to simple mistakes that can be easily avoided. By understanding these common errors, you can ensure optimal performance and longevity of your equipment.

Skipping Pre-Rinse Steps

Failing to pre-rinse kegs can leave behind debris that affects the final cleaning results. Residue left in kegs can harden over time, making it more difficult to remove during the sanitation cycle.

Using the Wrong Cleaning Agents

Different kegs may require specific cleaning solutions. Always use industry-approved chemicals for effective sanitation. Using inappropriate detergents can damage the keg’s interior lining and affect beer quality.

Not Regularly Maintaining the Keg Washer

Routine maintenance is necessary to keep the washer functioning efficiently. Clogs, worn-out parts, and improper pressure settings can reduce effectiveness. Regular inspections help identify small issues before they turn into major problems.

Ignoring Cycle Time Adjustments

Ensure that the cleaning cycle time matches the level of residue buildup in your kegs. Over-cleaning wastes resources, while under-cleaning can lead to contamination. Optimizing cycle time balances efficiency with thorough sanitation.

Conclusion

Choosing the best keg washer is essential for maintaining cleanliness, improving efficiency, and ensuring the highest quality beer production. By investing in a reliable keg washer, breweries can enhance productivity while maintaining high sanitation standards. Whether you operate a small craft brewery or a large production facility, selecting the right keg washer tailored to your needs will optimize operations.

Ready to upgrade your brewery’s cleaning process? Invest in the best keg washer today to improve efficiency and ensure top-quality beer for your customers!

FAQ

How often should I clean my kegs?

Kegs should be cleaned immediately after use to prevent contamination and residue buildup.

Can I use a manual keg washer for a growing brewery?

While manual keg washers are cost-effective, a growing brewery may benefit from upgrading to a semi-automatic or automatic system for increased efficiency.

Does a keg washer save money in the long run?

Yes, investing in the best keg washer reduces labor costs, optimizes water and chemical usage, and prevents beer contamination, ultimately saving money over time.