Our multi-effect stills use pure water as feed water and use industrial steam heating to produce water for injection (WFI). SKE’s LDS series of multiple effect stills use the same principle to produce Water for Injection (WFI) using industrial steam. The final product meets the requirements of the United States Pharmacopoeia (USP), European Pharmacopoeia (EP) and Japanese Pharmacopoeia (JP), ensuring it is suitable for pharmaceutical applications.

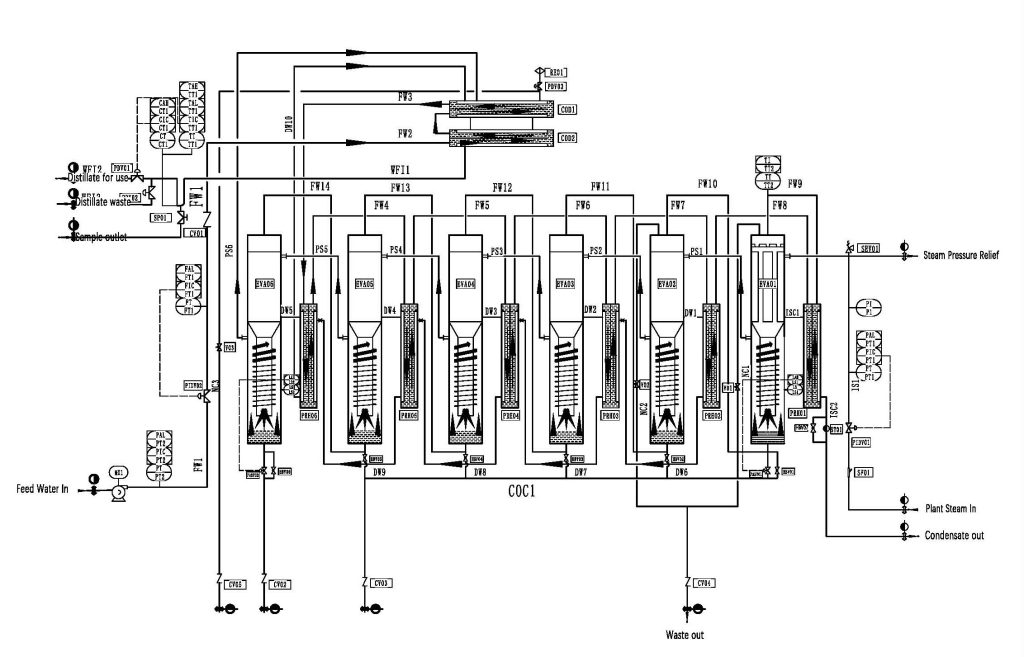

316L Stainless Steel Distillation Equipment Working principle

- Qualified feed water will pump into the condenser after increased the pressure by multistage centrifugal pump.

- Then pump into each preheaters.

- Get into 1st stage evaporator, spray into internal of heater to create film flow, heated by industry steam to create pure steam & water mixture.

- Pure steam and water mixture go through Steam Separator.

- Non condensate water will move to 2nd stage evaporator. Pure steam will be heating medium for 2nd stage evaporator.

- Pure steam from last stage mix with condensate from each stage evaporator ( except from 1st stage), discharge non condensate gas, become WFI after feed water analyzer.

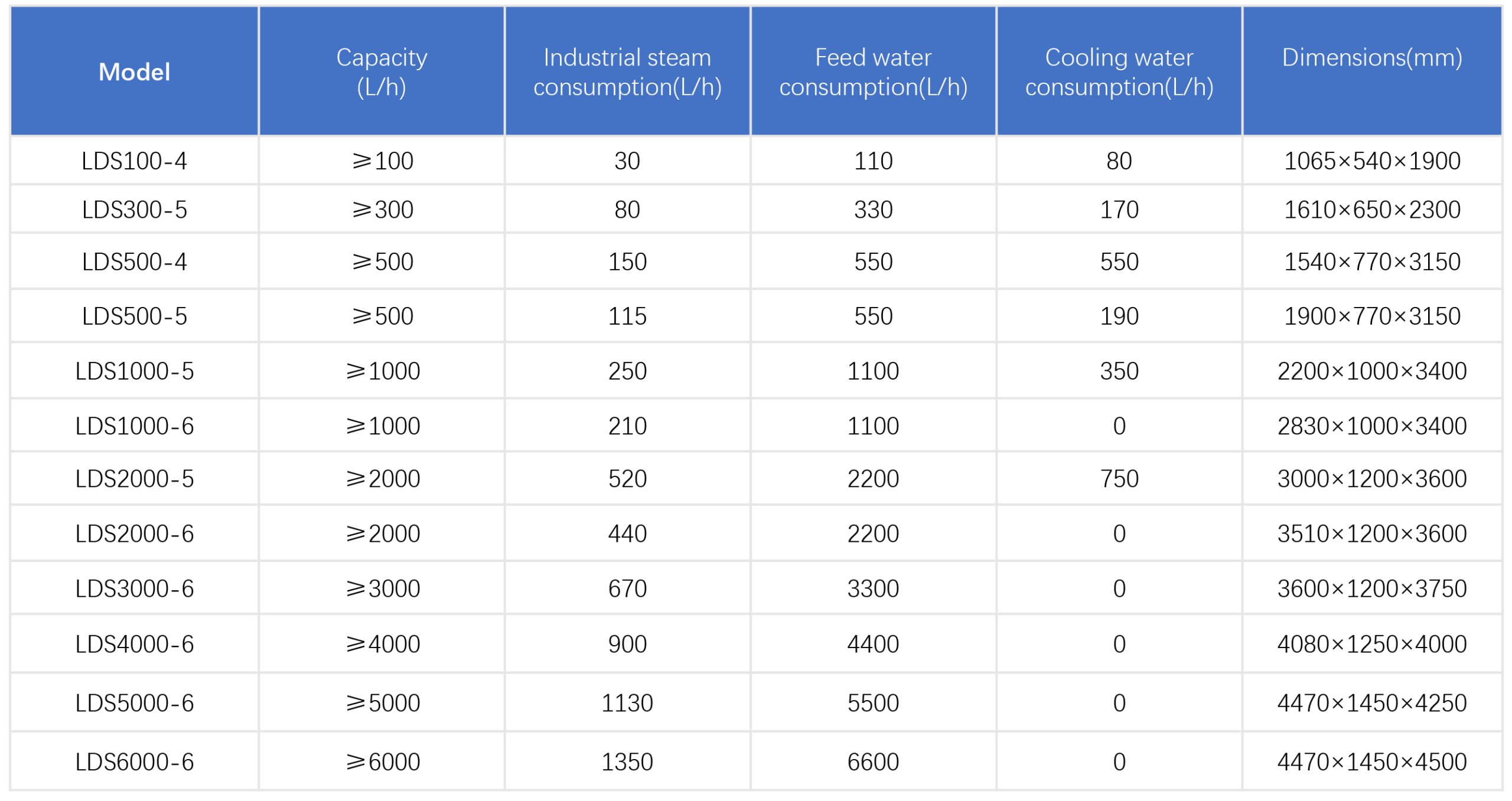

Energy-Saving Multi-Effect Distillation Specifications

Automatic CIP Pharmaceutical Stills Parameters

- Wet side Stainless Steel 316L, electropolish, Ra≤0.2um

- Advanced PLC Control System

- Automatic CIP

- Commercial kombucha fermenter easy assembly and disassembly

- Low point drain to make sure no residual.

- Automatic sterilize function when start up after long term stop.

- No dead legs

- Energy saving

- Double tube sheet for evaporator, preheater and condenser of 1st effect to avoid cross contamination.