In modern breweries, data is as important as ingredients. Large-scale production facilities often rely on comprehensive MES (Manufacturing Execution Systems) to track and manage every detail of the brewing process. But for smaller brewing systems, MES solutions are often far too expensive and unnecessarily complex.

On the other hand, relying solely on manual records brings its own problems—time-consuming, inconvenient, and often lacking the precision needed for meaningful analysis.

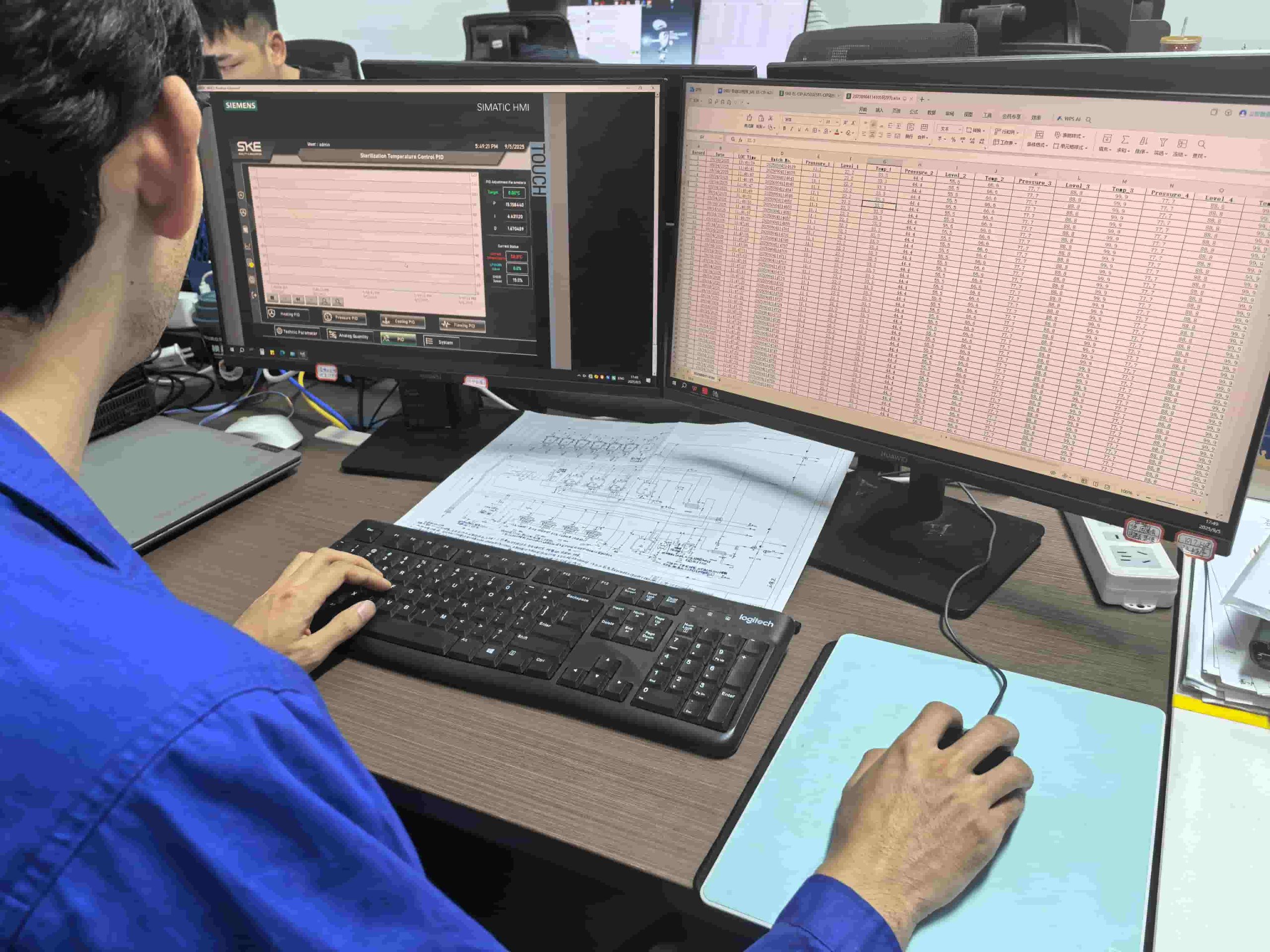

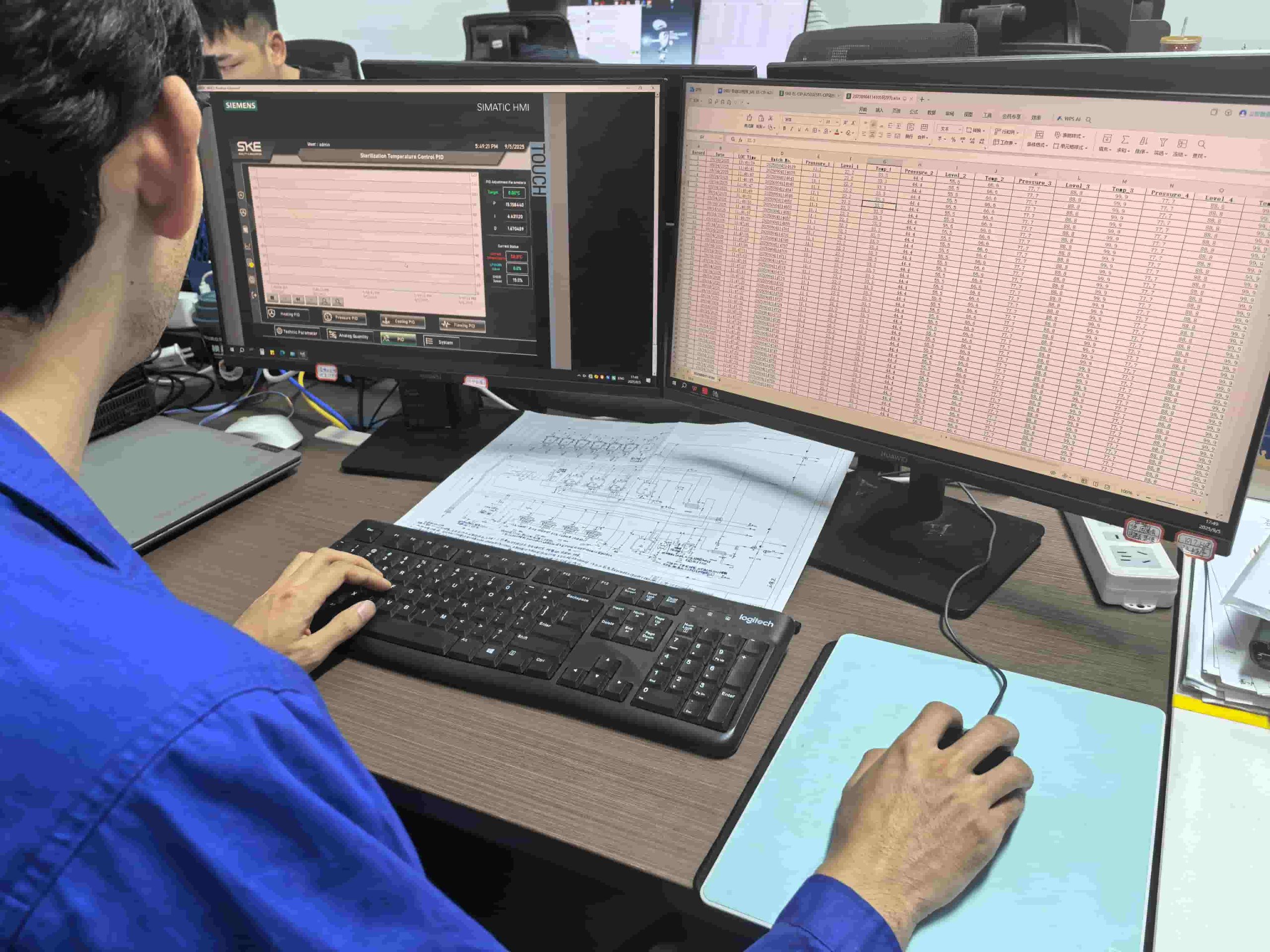

To solve this challenge, our software engineers at SKE have designed a Production Daily Report Program specifically tailored for small-scale brewing systems. It provides the right balance between cost, convenience, and efficiency.

What Does the Production Daily Report Include?

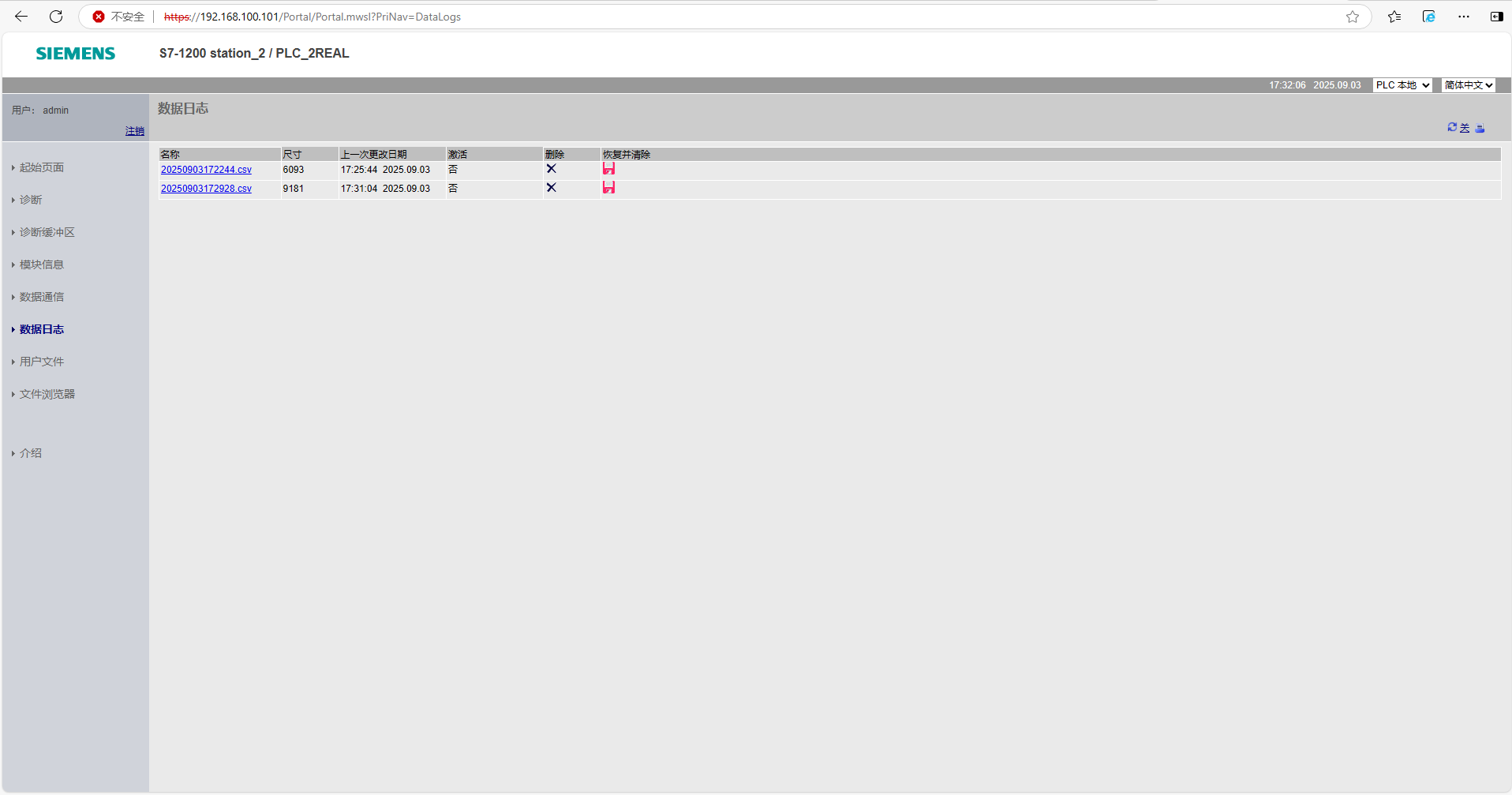

The system automatically generates a clear and structured report for each production batch, capturing all key parameters that brewers need to monitor:

-

Batch Number: Complete traceability of each production run.

-

Water Consumption: Including Mash-In water usage, Sparging & Transfer water usage, CIP water usage.

-

Temperature Data: Recording precise values for Mashing temperature, Boiling temperature, KnockOut temperature.

-

Tank Levels: Such as HLT level, CLT level, and wort level in the boiling kettle.

-

Additional Parameters: Including pressure and flow rates where applicable.

This data is collected in a structured format that can be stored, reviewed, and analyzed with ease.

Why It Matters: The Advantages

The main strength of this system lies in its ability to turn historical data into actionable insights:

-

📊 Monitor Production in Real Time – See how each batch is progressing without relying on guesswork.

-

⚙️ Analyze Efficiency – Identify bottlenecks, track water and energy usage, and improve overall productivity.

-

💡 Optimize Processes – Use precise data to refine brewing parameters and enhance consistency between batches.

-

💰 Low Cost, Big Value – Compared with full-scale MES systems, this solution requires only a fraction of the cost while still delivering significant benefits.

And this isn’t just limited to mashing. The same reporting approach can easily be adapted for other small-scale equipment such as pasteurizers, CIP stations, or auxiliary systems.

Conclusion

For small-scale breweries, investing in a full MES may not be practical. Yet, accurate data recording and analysis remain essential for improving efficiency and ensuring consistent product quality.

SKE’s Production Daily Report Program bridges this gap—an affordable, lightweight solution that empowers brewers with the data they need, without the complexity or high cost of traditional systems.

Sometimes, the simplest solutions create the biggest impact.

👉 Contact SKE today to learn how we can help you digitize your brewing operations efficiently and cost-effectively.